Everything About Membrane Switch: Understanding Its Style and Performance

When you assume concerning the control interfaces in modern tools, membrane layer buttons often come to mind. Allow's explore what collections membrane switches over apart from other control systems.

What Are Membrane Switches?

Membrane buttons can likewise be personalized relating to shape, dimension, and graphics, enabling manufacturers to produce distinct interfaces tailored to specific items. Overall, membrane layer buttons play a substantial role in improving individual experience across a vast selection of applications.

Exactly How Membrane Changes Work

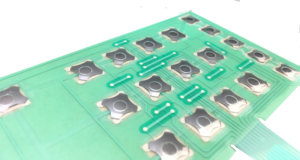

When you push a trick on a membrane layer button, it triggers a simple yet efficient system. The top layer, typically constructed from versatile product, lowers onto a conductive layer under it. This action bridges the void between conductive traces, completing an electric circuit. As quickly as the circuit shuts, it sends a signal to the device's controller, which interprets your input.

You'll see that the tactile feedback differs based upon the button layout, providing either a soft click or a much more obvious reaction. As soon as you release the secret, the membrane returns to its initial placement, reopening the circuit and quiting the signal. This process occurs nearly instantly, making sure a responsive individual experience.

Membrane layer switches are popular because of their sturdiness and resistance to dirt and dampness, making them perfect for various applications, from house appliances to clinical gadgets. Comprehending this operation helps you value their widespread usage.

Key Elements of Membrane Layer Switches

Recognizing the key components of membrane switches is essential for comprehending their performance and layout. At the core, you'll locate the visuals overlay, which provides the aesthetic user interface for individuals. Under that, there's a spacer layer that divides the circuit layers, ensuring that they do not make get in touch with till pushed. The circuit layer is where the magic happens; it is composed of conductive traces that finish the circuit when you press the switch. An additional crucial aspect is the sticky backing, permitting the button to follow surface areas securely. The protective layer shields versus ecological elements and wear, extending the button's life expectancy. Each part plays a substantial role in making certain reliable performance and user communication. By comprehending these components, you'll obtain understanding right into how membrane switches operate and their value in numerous applications.

Materials Used in Membrane Change Layout

The performance and resilience of membrane changes heavily depend upon the materials utilized in their layout. You typically run into polyester and polycarbonate as key substratums due to their superb toughness and versatility. These products stand up to scrapes and chemicals, making them suitable for requiring environments.

The conductive layers often make use of silver or carbon, selected for their integrity and conductivity. membrane switch manufacturer. Silver provides exceptional performance, while carbon is an economical alternative. For the overlay, you might consider a matte or shiny coating, depending on your visual demands and user experience

Make particular to select adhesives that endure ecological elements like temperature level and moisture. Selecting the appropriate materials will certainly ensure your membrane button stands the test of time.

Style Considerations for Membrane Buttons

While designing membrane layer buttons, it's crucial to take into consideration numerous elements that affect their performance and customer experience. Beginning by concentrating on the design and switch size; make particular they're intuitive and simple to navigate. Consider the tactile feedback you intend to supply-- will individuals need a visible click or a softer touch? Furthermore, think of the materials you'll use, as they'll affect longevity and aesthetics.

Don't ignore the graphic style; clear labeling and color contrast are significant for presence. Confirm address your style suits environmental factors, like dampness or temperature variations, which can affect performance. Keep in mind the value look these up of testing models with actual users to gather feedback and make required changes. This iterative process assists you improve the layout, validating it satisfies both functional and visual needs efficiently. By thoroughly taking into consideration these elements, you'll create a membrane switch that improves usability and contentment.

Applications of Membrane Buttons

Membrane switches are functional elements found in numerous applications, from industrial equipment to customer electronic devices. You'll see their influence in machines that require durable user interfaces and in devices that take advantage of streamlined designs. Understanding these applications helps you value the functionality and functionality of membrane layer switches in day-to-day innovation.

Industrial Equipment Usage

When you're looking to enhance the performance of commercial tools, membrane switches supply a dependable option that integrates toughness with straightforward design. These buttons are excellent for severe environments, providing resistance to dirt, dampness, and chemicals. Accept membrane layer buttons to enhance your procedures and boost overall performance.

Customer Electronics Combination

In the domain of consumer electronic devices, membrane buttons play a crucial role in improving user communication and device performance. Membrane layer switches additionally ensure resilience and resistance to dust and wetness, extending the life expectancy of your electronic devices. By choosing membrane layer switches, you boost not simply the functionality yet also the design of your gadgets, making daily communications smooth and enjoyable.

Advantages and Negative Aspects of Membrane Switches

While membrane layer buttons supply a variety of benefits, they also feature some disadvantages that you need to consider. One considerable benefit is their compact style, making them ideal for space-constrained applications. They're likewise economical, supplying a durable option with a reduced manufacturing expense. On top of that, their seamless surface area is simple to tidy, improving health in settings like medical facilities.

Membrane switches can have a shorter life-span contrasted to mechanical buttons, specifically under heavy use. They can also be less tactile, which may affect individual comments during operation. Stabilizing these pros and disadvantages will certainly aid you identify if membrane layer buttons are the ideal fit for your project.

Often Asked Questions

For How Long Do Membrane Layer Switches Normally Last?

Membrane layer switches over normally last in between 5 to one decade, depending on use and ecological conditions. You'll wish to examine elements like wear, direct exposure to wetness, and temperature fluctuations to evaluate their long life efficiently.

Can Membrane Layer Switches Be Personalized for Particular Designs?

Yes, you can personalize membrane buttons to fit certain designs (membrane switch manufacturer). You'll have the flexibility to select shades, shapes, and layouts that match your task's my review here needs, guaranteeing they blend effortlessly with your general visual

What Is the Price Range for Membrane Layer Switch Production?

The price array for membrane layer switch production commonly falls between $1 and $10 per unit, depending on elements like design complexity, quantity, and materials. You can obtain quotes from makers to discover the very best option.

Are Membrane Switches Waterproof or Resistant?

Membrane layer switches can be developed to be water resistant or resistant, relying on materials made use of and construction techniques. If you need them for wet environments, guarantee you define those needs during the layout procedure.

How Do Membrane Changes Compare to Standard Switches?

Membrane switches are normally thinner and a lot more versatile than conventional buttons, using a smooth design. They're usually much easier to clean and integrate, but might not supply the responsive feedback you're used to with mechanical alternatives.

Final thought

Comments on “Don’t miss the value of working with a proven membrane switch manufacturer for prototypes.”